3D Printed Engines: Advanced Designs & Home Prints

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

Additive manufacturing has been used in transportation industries for a long time. Beginning as a means of cheaply prototyping various parts, the technology had evolved to the point where 3D printed engines are now a very real possibility.

- Can An Engine Be 3D Printed?

- How are Transport Industries Using 3D Printing?

- Industrial 3D Printed Engines

- Rocket Lab 3D Printed Engine

- 3D Printed Jet Engine

- SpaceX SuperDraco

- AI-Designed 3D Printed Rocket Engine

- Relativity Space

- Making a 3D Printed Engine at Home

- Working Mini 2JZ Engine

- Curtiss ‘Number 3’ Engine

- Working Oscillating Steam Engine MKI

- Toyota 4 Cylinder Engine 22RE

- Motorized 3D Printed Jet Engine

- 3D Printed Compressed Air Engine

- Bonus: Stirling Engine 3D Print Kit

Of course, 3D printing an engine isn’t a simple process. Engines are complicated pieces of machinery that require a high level of engineering knowledge to understand let alone design and build. And those with such knowledge have been designing and creating 3D printed engine models that really work.

But can an engine really be 3D printed? Here we’re going to look at the facts of the matter, as well as some of the most impressive uses of 3D printing in transportation as well as a few homemade 3D engine models you can even make yourself at home.

Can An Engine Be 3D Printed?

In short, yes. 3D printing working engines is possible, but just like traditional engines, it is an extremely complicated and precise process. But if you’ve got enough know-how, or are at least very willing to learn, then you can 3D print an engine of your own.

Whether you’re looking to 3D print an engine yourself, or are simply interested in how additive manufacturing has furthered the travel industry, then you’ll find all your answers here.

How are Transport Industries Using 3D Printing?

The professional applications of 3D printed engines and various parts have provided a massive boon to the transportation industries. 3D printed parts are a lot cheaper than traditionally made pieces, and they save a lot of time too.

Arguably, using 3D printing for mechanical engineering is also a lot more eco-friendly. Reducing the need for importing and exporting parts and instead making them in-house is a much greener method.

As well as this, the lightweight nature of 3D printed parts helps greatly in parts for cars like those used in Formula 1. Using less heavy 3D printed engine parts and even interiors lower the overall weight of the cars and makes them capable of hitting higher speeds.

If you’d like to learn more, then why not check out how 3D printing has been used in the automotive industry?

Going beyond cars, 3D printing has been embraced by collectives like NASA and SpaceX to take advantage of the money- and time-saving nature of additive manufacturing. Aeronautical companies like Boeing have also turned to 3D printed jet engine prototypes to cut down on cost and weight when developing newer models.

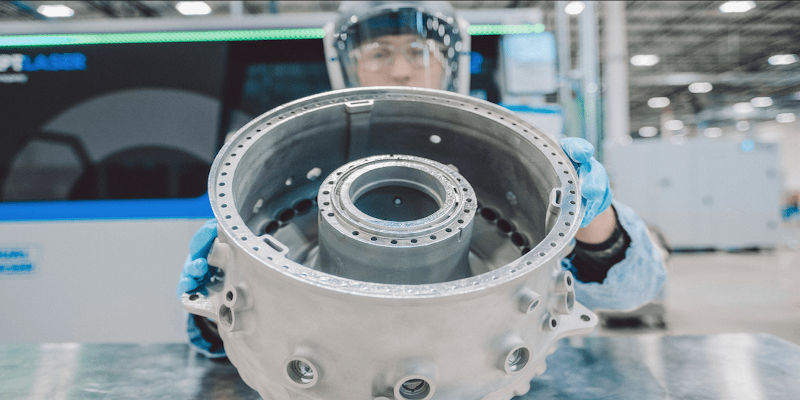

Industrial 3D Printed Engines

Beginning with the leaps and bounds made in professional sectors, we’re going to look at the major ways 3D printing has already been used to make engines and engine parts. And we’re not just talking about 3D printed car engines, but jets and even space travel too.

Rocket Lab 3D Printed Engine

Rocket Lab is one of the most exciting space travel companies out there. Pairing up with other ventures like NASA and the United States Space Force, they’ve made some impressive strides in the field of astronautical travel and engineering.

Being no stranger to the advantages of additive manufacturing, the Rocket Lab 3D printed engine, known as the Rutherford, is a marvel of technology. Being almost entirely printed, the Rutherford engine is a lightweight and cost-effective rocket that began testing in 2013 and is still used in successful missions to this day.

3D Printed Jet Engine

Several years ago, General Electric set out to design and test a 3D printed jet engine. Capable of revving up to 33,000 RPM, the deceptively small engine was incredibly powerful and ready to test.

When prototyping reached a head in 2020, aeronautics manufacturers all over the world were showing immense interest in the future of using metal 3D printing to make fully working 3D printed jet engines.

Their video Additive and Aviation was released in 2018, and is no less exciting today, giving us all hope for the future of 3D printed jet engines and additive manufacturing’s potential in aeronautical transport.

SpaceX SuperDraco

Private space venturing company SpaceX may not be the most popular of companies these days, but that doesn’t mean they haven’t made some significant and exciting developments in recent years.

The SuperDraco engine heavily used 3D printing in its design to not only cut down on costs and material weight, but also add to the creative process by allowing design changes to be made and tested out quickly to speed up the process and arguably make the end result safer.

What came from this was the first never non-government-built spacecraft to safely transport cargo to and from space stations without incident. After understandably catching NASA’s attention, SpaceX is not working to create a space station using the 3D printed Draco engines to safely transport humans into space.

AI-Designed 3D Printed Rocket Engine

The name of this one may sound like a sci-fi writer’s fever dream, but the 3D printed rocket engine prototype designed by German company Hyperganic is all too real. Not only that, but it was entirely designed by an AI using complex algorithms to create a 3D printed rocket engine as one piece instead of using separate parts.

Not only is it one continuous piece, but it also incorporates a combustion chamber as well as an intricate cooling mechanism to prevent overheating, which is a common concern when using functional 3D parts.

This also removes the common worry in standard rocket engines, as the cooling system often needs to be attached separately through welding, which carries the risk of it breaking off in flight, which is extremely dangerous.

The fact that it was designed and made entirely automatically is a potential insight to the future of automotive engineering as well as additive manufacturing’s place in it. Not bad at all for something born from a Microsoft Excel document.

Relativity Space

Not only is astronautical company Relativity Space using 3D printed engines to power many of their creations, they have also made huge leaps in creating entirely 3D printed rockets. Like the AI-Designed 3D printed rocket engine above, Relativity Space uses algorithms and autonomous robotics to create 3D printed engines and rockets in as little as 2 months.

There are many reasons why Relativity Space has turned to automatic processes and 3D printing. As well as cutting down on costs and streamlining the prototyping processes, 3D printing parts allows for the kind of precision and geometrical positioning that would be basically impossible through traditional means.

This does not sacrifice strength, however, as their flagship model, the Terran, is designed to be capable of carrying an ideal weight of 900kg (about the weight of an adult walrus) of cargo into space.

So keep an eye on Cape Canaveral in 2024, as Relativity Space hopes to begin launches of their 3D printed rocket engines there and then, promising safe, cost-effective, and highly impressive missions to orbit, the moon, and even Mars in the next few years.

Making a 3D Printed Engine at Home

While it’s highly unlikely that you have the hardware necessary to 3D print your own functional car engine (let alone space travel), you can still 3D print your own engine at home. These are great as standalone pieces or parts of larger projects if you’ve got your sights set a little higher.

As well as being great prints for anyone interested in engineering, these 3D printed engines, if made carefully, also make great educational tools. So if you’ve got the know-how and want to share it, then you can try any of these engines’ STL files at home.

Working Mini 2JZ Engine

- Where to Download: Thingiverse

- Designer: AxelDayton

- Price: Free

Since many of the engines we’re looking at here will be quite intimidating to a newcomer, I’ve decided to include this working mini 2JZ engine. It’s a simple, basic 3D printed engine model that should be approachable by newcomers as an introduction to 3D printing replicas for engineering.

While that’s not to say it’s an easy ‘press print and you’re done’ model, it is less dangerous and much less complicated than the actively working or motorized engines you can also 3D print with enough background knowledge.

The designer has listed this as a fixer-upper, meaning you’re more than welcome to add to or alter the model if you’re confident enough to do so. You can even take part in the 3D printed engine challenge issued by the creator as a fun exercise, just be sure to follow the instructions included in the link.

As a manually moving engine, it also works well as an educational toy for any older children in your life that you’d like to introduce to mechanical engineering.

Curtiss ‘Number 3’ Engine

- Where to Download: Thingiverse

- Designer: Erich_with_an_H

- Price: Free

First developed in the early 20th century, the Antoinette engine is an easily recognizable engine type that boasted improved acceleration and power in motor vehicles, which were still very new technology at the time.

The Curtiss is a 3D printed V8 engine modeled after the historic one used in part by Alexander Graham Bell and was used in the first ever motorized flight in Canada in 1909.

While not a working engine, this 1/8 replica model is a fantastically detailed 3D printed air engine that combines the twin passions of mechanical engineering and modern history. While since made more or less obsolete, this early model is a great monument to human ingenuity and advancement, leading to the convenient air travel we all know today.

Working Oscillating Steam Engine MKI

- Where to Download: Thingiverse

- Designer: cbabbage

- Price: Free

Speaking of historical breakthroughs, the steam engine – a major player in the industrial revolution – is one of humanity’s major steps into the future, and will be remembered for a long time to come.

This working 3D printed steam engine seems unassuming at first glance, but is an impressively designed piece that emulates the old tech with newer machinery, combining the historic and modern in a design that’s easy to print but difficult to understand.

As a MKI, the designer has paved the way for future models and further improvements to be made, making it an ideal stepping stone for those of you who want to 3D print your own takes on the steam engine.

Included in the link is a set of detailed instructions including any extra hardware you might need and several answers to FAQs, so you should be able to 3D print this steam engine with confidence regardless of your skill level.

Toyota 4 Cylinder Engine 22RE

- Where to Download: Thingiverse

- Designer: ericthepoolboy

- Price: Free

While most 3D printed engine blocks you can make at home may not be able to help with your commute (just yet), they are excellent for making working replicas of existing engines to either fit into a current project of yours, or help you better understand or teach how such engines work.

The Toyota 4 Cylinder engine here is a 3D printed engine model reverse-engineered from the real thing to work and move exactly the way a real engine does.

Any fan of mechanical engineering or even just cars will find this to be a challenging but rewarding print, though it will be quite time-consuming. 3D printing the block alone will take up to 40 hours, and you’ll need to take extra care in assembly to both get the desired results and make sure you don’t get hurt by the moving parts.

If you’re looking to learn or teach about engines and need a practical example of a relatively simple 3D printed car engine, then this is the print for you.

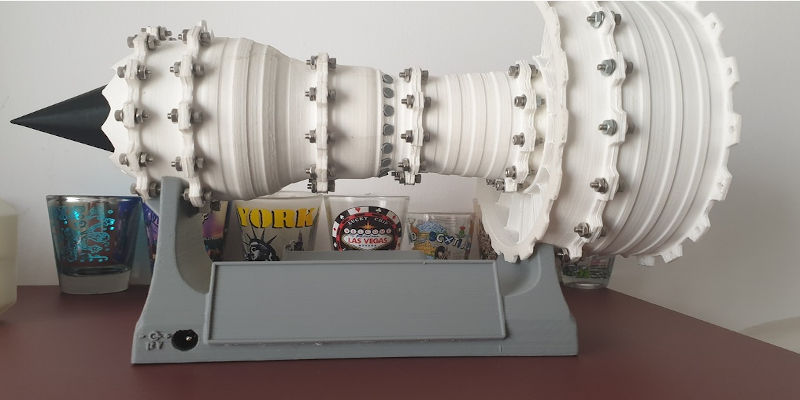

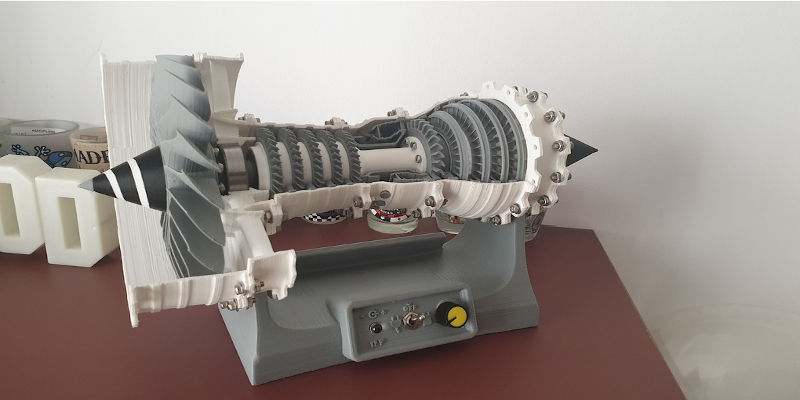

Motorized 3D Printed Jet Engine

- Where to Download: Thingiverse

- Designer: jimacid

- Price: Free

If you’re interested in engineering and printing your own engines, then this replica motorized 3D printed jet engine is a great project that is an excellent and active example of how jet engines work. Remixed from this portable version, the motorized jet engine shows a cross-section of the inner workings, making for a visually appealing display that fits well into any engineer’s workshop.

Of course, there is some wiring to do, and the pieces need to be printed to their precisely measured sizes in order to move together without wedging or forcing themselves undone. Dimensional accuracy is very important when 3D printing anything involving moving parts, especially motorized ones.

It’s been updated over time to be a more efficient print, and the entire thing works with a 1806 drone motor, though be advised that they tend to overheat if used for extended periods, so do not leave the motor running when you’re not around to observe it.

3D Printed Compressed Air Engine

- Where to Download: Thingiverse

- Designer: TomStanton

- Price: Free

Otherwise known as a pneumatic motor, a compressed air engine uses heightened air pressure to force kinetic energy onto moving parts. Think of a deodorant can or fire extinguisher to get a good idea of how they work.

Using compressed air in a relatively tight space as propellent, they are among the most dangerous and wasteful engine sources, but are fascinating nonetheless.

3D printing this compressed air engine will require a lot of hardware and some very careful work. Because of the nature of the power source, it is very important that you wear protective gear during construction and use.

I’ll be honest here, compressed air devices terrify me. Despite the heightened safety precautions necessary in modern-day production, I simply can’t stand them. As someone who used to work in bars and handled a lot of gas cylinders and highly pressurized kegs, I’m aware of how dangerous they can be.

I say this not simply to inject myself into this article, but also to warn you that this is not a 3D printed engine for beginners and should be taken on only by those who know what they’re doing when handling particularly sensitive equipment.

Bonus: Stirling Engine 3D Print Kit

- Where to Download: Stirling Engines

- Price: $38.49

The 3D printed Stirling engine is another engine that uses air as an energy source, changing the temperature to make the parts move in a fully working engine print.

The price of the kit covers all files, instructions, and necessary hardware to print your own low-temperature version of this oft-overlooked engine type.

Related Articles: