3D printing technology has come a long way in recent years and is still constantly evolving. One of the most recent innovations is the creation of the conveyor belt 3D printer.

Conveyor belt 3D printers, or just belt 3D printers, are a fairly new innovation designed to make 3D printing easier and more efficient, but aren’t very widely known yet. So what exactly are conveyor belt 3D printers, how do they work and what are they used for?

We answer those questions and more in this guide to conveyor belt 3D printing. Once we’ve explained what conveyor belt 3D printers are and how they’re beneficial, we’ll then review the top models on the market in case you’d like to buy one for yourself.

What is a Conveyor Belt 3D Printer?

As the name suggests, a conveyor belt 3D printer uses a belt as a bed so that you can print continuously. This means you can easily mass-produce small models and print large parts that wouldn’t be possible, or would at least be a lot more difficult, with a regular 3D printer.

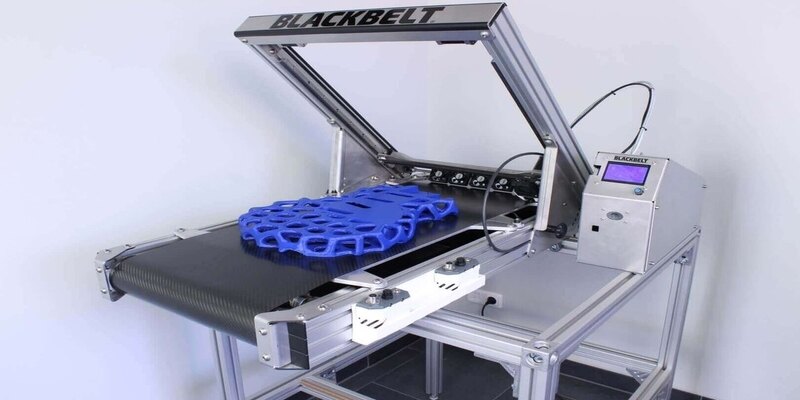

Conveyor belt 3D printing is still a relatively new technology that came about in 2017 when the Dutch company Blackbelt 3D released its first model. Several other companies have since followed suit in exploring conveyor belt 3D printing, although these types of printers are still currently restricted to just a few manufacturers.

Although these printers are more expensive than regular ones, they have intrigued many 3D printing enthusiasts, both hobbyists and professionals. So, how exactly do they work and in what kind of situations would a 3D printer belt suit you? Let’s find out.

How Does 3D Printer Belt Technology Work?

Conveyor belt 3D printers use fused deposition modeling (FDM) technology. This is where materials are fused together by melting them just past their glass transition temperatures and then layering them on top of each other to create an object.

However, they are different from other FDM printers, such as Cartesian, polar, Scara, and delta models, as they use tilted nozzles. Whereas a standard Cartesian frame has its top tilted sideways, 3D belt printers have a CoreXY gantry in which one side is tilted down. The angle is typically 45 degrees, although it can be smaller.

If you’re unsure what these mean, read: the main types of FDM 3D printer

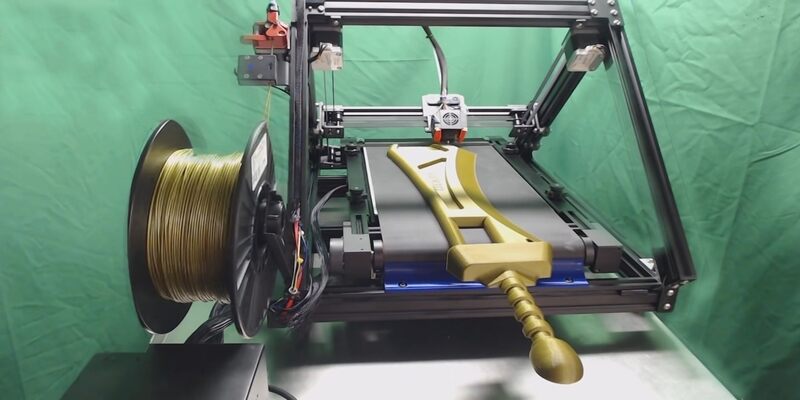

In a 3D belt printer, the machine the X and Y axes are rotated at an angle rather than being parallel to the build plate. The Z-axis build plate itself is placed with a conveyor belt, meaning there is infinite build potential along the Z-axis.

During printing, the belt pulls prints away from the nozzle. The hot end is suspended in the CoreXY gantry and travels within a titled XY plane, whereas the belt travels along the Z-axis, meaning it can in theory print objects of infinite length.

Of course, prints would eventually fall off the belt, but this can be avoided simply by having a support structure in place. If you have this, which could be anything from a beam at the printer’s height or a set of rollers in front of the bed, then you can print objects with no length restrictions.

Conveyor Belt 3D Printers Uses & Applications

The fact that a conveyor belt 3D printer can be used for continuous printing offers two main benefits – the ability to mass-produce small models and the ability to print extremely large models. This means they’re particularly well suited for semi-automated or fully automated production.

A 3D printer belt means the machine can automatically remove objects so that it can start the next job as soon as one part is done, massively increasing productivity. In terms of model size, this type of printer can print infinitely long objects in the Z direction, so you’re not limited by the size of the build platform like you are with regular printers.

These aren’t the only advantages, though. With a conveyor belt 3D printer, there’s no loss in average print speed, print removal is automatic and hassle-free, and it’s also possible to have a partially heated printing bed.

In most cases, conveyor belt 3D printers are best suited to professionals working in business and industry. This is due to the types of projects they’re best suited for, their size and their expense. That’s not to say that they’re not useful for serious hobbyists, but that they’re outside the scope of beginners and casual 3D printing hobbyists.

If you’re considering purchasing a conveyor belt 3D printer, it’s important to consider the limitations as well as the benefits. For example, in addition to the high prices and requirement of additional support structures, these types of printers print at relatively slow speeds, can’t print in ABS and some other materials, and you can’t have glass print beds.

The Best Conveyor Belt 3D Printers to Buy

If you’ve read our guide and fancy buying a conveyor belt 3D printer for yourself, here are our recommended printers that you can purchase today.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

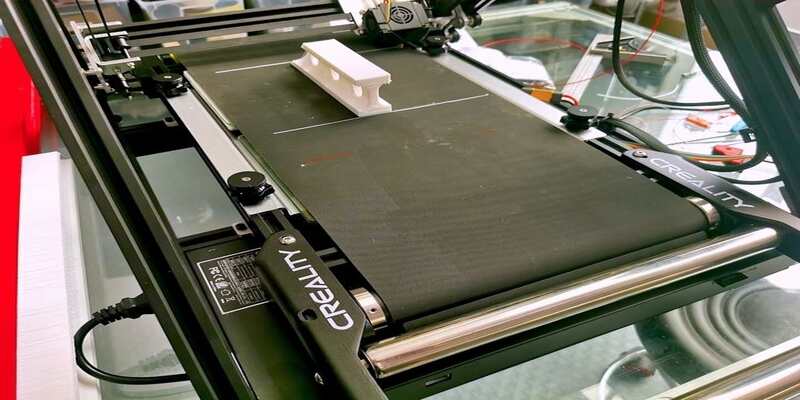

Creality CR30 – Overall Best Conveyor Belt 3D Printer

- Price: $1,049 — Available at Creality Store here / Available at Amazon here

Pros

Very sturdy and robust.

Ultra silent motherboard and chip for quiet printing.

Strong adhesion and well-balanced conveyance.

Cons

The interference can feel outdated.

The Creality CR30 is currently the best and most popular conveyor belt 3D printer on the market. This model has set the benchmark for this type of 3D printer.

For starters, it has an extremely stable CoreXY precision structure with isosceles right triangle support. This means the printer is very sturdy and robust, offering an overall very smooth experience.

The conveyor belt itself is made of wear-resistant nylon for durability, extending the working life and enabling the printer to work to a high level over long periods of time. It has strong adhesion, well-balanced conveyance, and offers simple removal of products, as it has a removable extension bracket to prevent models from falling during printing.

This belt 3D printer has an all-metal frame that’s designed to minimize vibrations from the Core-XY motion gantry for smoother, more stable printing. The nozzle can reach temperatures of 240°C, so it’s capable of printing a wide range of materials including TPU and PETG.

Thanks to the high-quality dual gear metal extrusion mechanism, as well as the 45 degrees slanting nozzle, this printer is capable of printing for over 200 hours at a time. The printing bed itself has a max temperature of 100°C, so it provides plenty of adhesion for printing polymer parts. You can easily level the bed using the knobs on the edges of the conveyor belt.

Another really useful feature is the filament breakage detector. It has a smart sensor that suspends printing whenever the filament runs out or there is a breakage, and then printing resumes automatically after you have fed in the new filament.

This printer comes in four separate parts – the base, front, rear, and control panel – but it’s simple to set up and should only take half an hour or so to get started.

Finally, this 3D belt printer comes with the CrealityBelt slicer software included. With the software, you can slice a model of any length as well as multiple models in a line, and the package includes ready-made slicing profiles developed by Tom Jackson, a well-known slicer expert.

Blackbelt 3D – Excellent 3D Printer Belt for Industrial Settings

- Price: Upon inquiry

Pros

Comes with Bowden set up standard, working well with rigid materials.

Adjustable angles.

One of the best on the market.

Cons

Very expensive.

List one of the cons/drawbacks

Blackbelt was the trailblazer of 3D belt printing with the release of its own model back in 2017, and it’s still one of the best on the market.

There are actually two purchasing options for the Blackjack 3D conveyor belt printer. You can choose the standalone version which consists of the printing platform with the controller and support construction, or you can go for the roller table version which has an extended support table capable of supporting prints of two meters.

You also have the option of adding a VarioDrive setup extension to your printer. It comes with a Bowden set up as standard, which works well with rigid materials. If you go for the VarioDrive setup, you’ll be able to print with a wide range of flexible materials, as well as nylon and carbon-filled filaments.

There is a choice of angles from 15 to 45 degrees, so you can adjust it based on your production needs. The belt is made from carbon fiber, so it’s lightweight yet incredibly durable.

While this is an exceptionally high-quality machine, it doesn’t come cheap. You have to request a quote from the company before you can get a firm price, but the average cost is around $10,000. The higher price means that this machine is best suited to business and industry, whereas the Creality machine is more open to hobbyists.

Other Conveyor 3D Printer Belt Machines

While the Creality and Blackbelt machines are the best 3D belt printers on the market for both hobbyists and professionals, they’re not the only choices you have. Here are some other machines worth checking out if you’re looking to purchase a 3D belt printer.

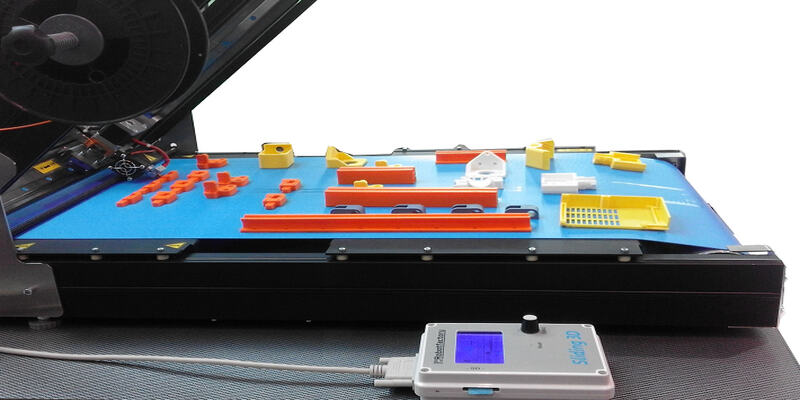

Powerbelt3D Zero

- Price: around $500

Pros

Affordable.

Great benefits such as a semi-heated bed, an all-metal hot end, and it can print multiple filaments.

Cons

Not visually pleasing.

This is another low-price conveyor belt 3D printer that’s designed to make the technology more accessible to hobbyists. It’s certainly not as visually appealing as the Creality or Blackbelt machines, but it does have some benefits. For example, it has a semi-heated bed, an all-metal hot end, and it can print flexible filaments such as TPU.

You’ll need to request a quote if you want to buy the Powerbelt3D Zero.

iFactory One

- Price: $999

Pros

Durable.

The nozzle and other parts are custom-made.

Comes with a webcam and OctoPrint software built in.

Cons

Poor quality components.

The iFactory One 3D printer belt was released around the same time as the Creality machine and has some nice features. The belt was made in conjunction with one of the world’s biggest belt manufacturers for optimum durability, the nozzle and other parts are custom-made, and the drone also has Raspberry Pi, a webcam and the OctoPrint software built in.

This conveyor belt 3D printer will set you back $999.

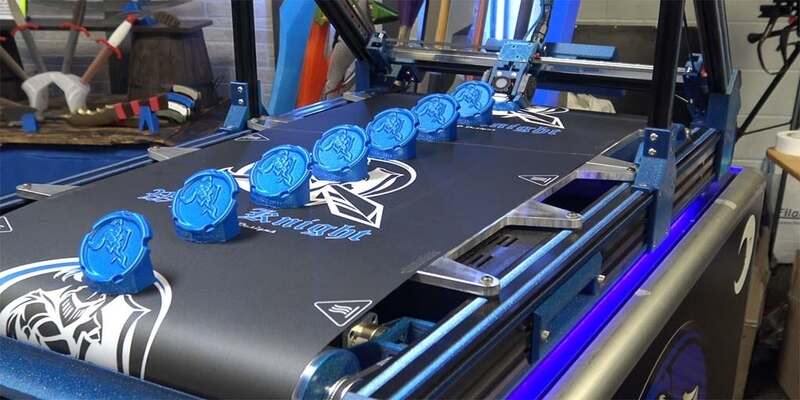

The White Knight

- Cost: around $2,000

Pros

Open-source DIY project.

Fun and challenging project.

Cons

Quality isn’t as good as with Creality or Blackbelt 3D.

Whereas the printers we’ve profiled so far are complete models you can purchase as one, the White Knight is an open source DIY project in which you build the printer yourself. The total cost comes to around $2,000, and you don’t get the quality you get with the Creality or Blackbelt 3D printer belt machines. However, it’s certainly a fun and challenging project for 3D printing DIY enthusiasts and comes with a lot of community support.